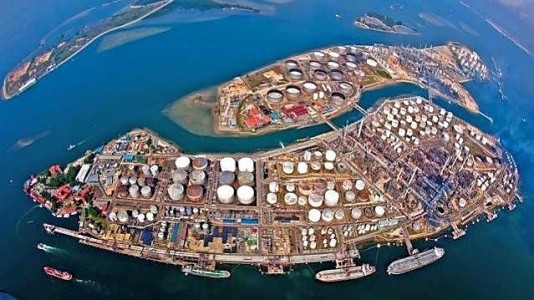

Shell Singapore is piloting a total of 4,000 COVID-19 contact tracing devices for its employees, contractors workers and visitors at its Pulau Bukom facility, which is located in a small island five kilometres south of the city state.

The oil and gas company has tapped D’Crypt to deploy specially modified BluePass devices that will be safe to use in an environment where flammable gases maybe present. This is the first time a modified version will be tested in a live process plant environment.

If successful, this pilot could pave the way for the modified devices’ use across the process industry in Singapore and abroad. According to Singapore’s Ministry of Manpower, there are 60,300 workers involved in the petroleum, chemical & pharmaceutical products sector in the city.

“Currently, the contact tracing of individuals within the process areas can take hours, which slows down the process of identifying and isolating close contacts. The enablement of prompt contact tracing for process industry workers in Singapore will substantially mitigate the risk of a COVID-19 outbreak in the community,” said Hugues Bourgogne, Shell’s vice president for manufacturing in Singapore & Philippines and General Manager of Bukom.

“Through this pilot of the modified BluePass devices, we are glad that Shell Singapore can play a role in enabling Singapore’s economic activities to ramp up while keeping our workers safe from COVID-19,” he added.

Thorough evaluation

Shell has evaluated the modified BluePass devices for their safe use at the process areas in the manufacturing site at Pulau Bukom using IEC (International Electrotechnical Commission) standards commonly referenced by process industry companies worldwide, as well as guidance from EEMUA (Engineering Equipment and Materials Users Association) and EI (Energy Institute).

Shell applies these standards for any equipment used in their facilities since there may potentially be flammable gases present. The evaluations included the ruggedness of the body of the modified BluePass device, protection from user tampering or maltreatment, the power source and size of the battery, as well as the energy level transmitted during use.

The pilot of the modified BluePass devices will run until March.

“Shell’s evaluation of BluePass gives us confidence to conduct further pilots of the device for use in real-world production environments. We have full confidence that process industry players will be able to successfully put the BluePass through a similar evaluation for effective contact tracing without endangering lives or compromising operations at their facilities,” said Dr. Antony Ng, CEO of D’Crypt.

D’Crypt is a security engineering company owned by Temasek Holdings. The company developed BluePass, a small, battery-powered, wearable device last year for distribution to the public. It exchanges proximity information with other BluePasses or interoperable devices via Bluetooth Low Energy (BLE) technology, and stores that information for a stipulated period for contact tracing purposes. BluePass safeguards user privacy by not tracking location information.

Once the pilot at Shell Pulau Bukom is completed, both companies will proactively share results – both in terms of effective contact tracing and BluePass’ suitability for use in live process plant environments − with the process industry in Singapore.

“We hope this will contribute to a broad adoption of contact tracing devices in the process sector, dramatically improving Singapore and the world’s COVID-19 security.” said Dr Ng.